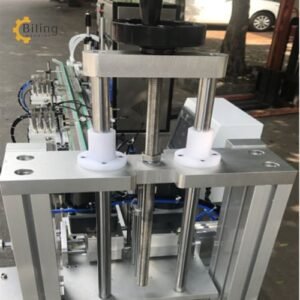

4 Wheel Bottle Screw Capping Machine Supplier

We are a trusted supplier of 4 Wheel Bottle Screw Capping Machines, offering reliable, high-quality solutions to enhance your production efficiency and ensure secure capping for various bottle types.

Machine Parameter

- Style no.: XGJ-1D

- Size: 760×1450×2000 mm

- Weight: 350(kg)

- Degree:Full-auto

- Power: 1(Kw)

- Power Supply: Customize

- Production Capacity: 10-30 times/minute

Features Of 4 Wheel Bottle Screw Capping Machine

PLC touchscreen control for easy operation

The PLC touchscreen control offers easy operation with a user-friendly interface, ensuring efficient and precise control.

Positioning device ensures precise capping

The positioning device guarantees precise capping, enhancing accuracy and consistency for optimal sealing performance.

Supports various bottle cap sizes

The machine supports various bottle cap sizes, ensuring versatility and compatibility with different packaging needs.

Movable casters for easy transport

Movable casters provide easy transport, allowing effortless relocation of the machine within the production area.

Wheel Bottle Screw Capping Machine Solution

This fully automatic capping machine is designed for industries such as daily chemical, pharmaceutical, and food production. It efficiently caps spray heads, pump caps, round bottle caps, and duckbill caps, providing a secure and consistent seal. With an electric and pneumatic control system, it ensures smooth operation and high stability, making it suitable for large-scale production.

The machine supports various bottle shapes and sizes, with adjustable capping speed and tightness to meet different requirements. A built-in positioning device helps align bottles accurately, reducing errors and ensuring reliable performance. Its touchscreen control system makes operation straightforward, allowing users to set parameters quickly and efficiently.

Designed for ease of use, this capping machine requires minimal manual effort. Quick adjustments allow smooth transitions between different cap sizes, improving production efficiency. The durable construction ensures long-term reliability, even with continuous operation. Movable casters make it easy to transport and reposition as needed.

For businesses seeking an alternative to manual capping, this machine is a practical choice. It reduces labor costs, increases output, and enhances consistency in sealing. Whether used for cosmetics, pharmaceuticals, or food packaging, it delivers fast, precise, and efficient capping for a wide range of applications.

More Technical Parameters:

Operating Voltage: AC220V 50/60Hz

Capping Torque: 4–8 kgf/cm

Maximum Power: 800W

Cap Diameter: 20–65mm

Conveyor Belt Height: 80–85cm

Capping Range: 20–65mm

Air Consumption: 0.4–0.6 MPa

Capping Speed: 10–40 bottles/min

Capping Qualification Rate: ≥99%

Applicable Bottle Height: 70–300mm

Weight: 90kg

Dimensions: 760 × 1450 × 2000 mm

Support & Service

If any technical issue comes up with the Wheel Bottle Screw Capping Machine in your facility, our team at Biling is ready to offer support. We can provide online assistance or, if needed, send an expert on-site to resolve the issue quickly.

We also offer marketing and branding help to our domestic and international distributors, ensuring they can effectively promote the machines. Our Wheel Bottle Screw Capping Machines are priced fairly and built to last, providing excellent value over time.

All our machines come with a 1-year warranty, so you can have peace of mind. If you need spare parts, we offer them at affordable prices to keep everything running smoothly.

Get Free Quote

Biling 4 Wheel Bottle Screw Capping Machine

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Quick Link to Know More About

Screw Capping Machine

FAQ of 4 Wheel Bottle Screw Capping Machine

What is a 4 Wheel Bottle Screw Capping Machine?

The 4 Wheel Bottle Screw Capping Machine is designed to securely screw caps onto bottles using four wheels for stability and consistent application. It is commonly used in industries like food, beverage, pharmaceutical, and cosmetics. The machine offers high efficiency, handling various bottle sizes and cap types. The Biling Machine, a notable model, ensures precise capping with adjustable settings, making it versatile for different production needs. It provides a reliable, automated solution for capping bottles at high speeds, improving productivity in large-scale production lines.

How does the 4 Wheel Bottle Screw Capping Machine work?

The 4 Wheel Bottle Screw Capping Machine works by aligning a bottle under a capping head, which places a cap on top. Four wheels then rotate around the bottle to apply consistent pressure, tightening the cap securely. This automated process reduces the need for manual intervention, ensuring speed and accuracy. The Biling Machine offers an efficient solution for large-scale production by precisely controlling the torque applied to the cap, preventing over-tightening or under-tightening. The machine is designed for high efficiency and can handle a variety of bottle and cap sizes.

Can the 4 Wheel Bottle Screw Capping Machine handle different bottle sizes?

Yes, the 4 Wheel Bottle Screw Capping Machine is versatile and can handle various bottle sizes. It is equipped with adjustable settings that allow quick customization for different bottle types, whether small or large. The Biling Machine, for example, can be easily adjusted to accommodate bottles of different diameters and heights. This flexibility makes it suitable for businesses that need to change between product lines or packaging formats without significant downtime, ensuring continuous and efficient operation.

Is the 4 Wheel Bottle Screw Capping Machine easy to operate?

The 4 Wheel Bottle Screw Capping Machine is designed for ease of use. With a user-friendly control panel and intuitive settings, operators can quickly set up and adjust the machine for different bottle sizes and cap types. The Biling Machine offers a straightforward interface with easy-to-understand instructions, making it accessible to operators with minimal training. Automation ensures consistent capping, reducing human error. The machine’s simple design and efficiency minimize operational complexity while maximizing output, making it a reliable choice for high-volume production.

What types of caps can the 4 Wheel Bottle Screw Capping Machine handle?

The 4 Wheel Bottle Screw Capping Machine can handle a wide range of cap types, including plastic, aluminum, and metal screw caps. It is also suitable for tamper-evident closures and other specialized caps. The Biling Machine is particularly versatile, designed with adjustable features to accommodate various cap sizes and shapes. Whether you are working with standard caps or more complex designs, the machine can be set up to provide the correct torque, ensuring a secure and efficient seal for each bottle.

Can the 4 Wheel Bottle Screw Capping Machine handle high production volumes?

Yes, the 4 Wheel Bottle Screw Capping Machine is designed to handle high production volumes. It features an automated capping process, allowing for continuous operation at high speeds without compromising quality. The Biling Machine, specifically, is known for its efficiency and reliability in high-output environments. With adjustable speeds, the machine can match the pace of your production line, ensuring that bottles are capped quickly and consistently, making it ideal for businesses that require large-scale operations without significant downtime or loss of performance.

What safety features does the 4 Wheel Bottle Screw Capping Machine have?

The 4 Wheel Bottle Screw Capping Machine, including models like the Biling Machine, is equipped with several safety features. These include emergency stop buttons to quickly halt the machine in case of malfunction, safety guards to protect operators from moving parts, and sensors to monitor bottle alignment. If a bottle is placed incorrectly, the machine stops to prevent damage or incorrect capping. These safety features help create a secure working environment, minimizing the risk of accidents and ensuring smooth operation during production.

Can the 4 Wheel Bottle Screw Capping Machine be customized?

Yes, the 4 Wheel Bottle Screw Capping Machine can be customized to suit specific production requirements. The Biling Machine, for example, can be adjusted to handle different bottle sizes, cap types, and production speeds. Customization may include adding features like extra capping heads or automated bottle handling systems. This flexibility allows businesses to optimize the machine for their unique needs, improving production efficiency. Customization options ensure that the machine can adapt to various product lines, helping companies maintain high levels of productivity and versatility.

What is the warranty for the 4 Wheel Bottle Screw Capping Machine?

The 4 Wheel Bottle Screw Capping Machine typically comes with a standard 1-year warranty, which covers any manufacturing defects or issues within the first year of operation. This warranty ensures that any problems arising from the machine’s construction or components will be addressed, providing peace of mind for the operator. After the warranty period, businesses can purchase replacement parts and continue receiving technical support to maintain optimal performance. Routine maintenance and proper care will help extend the machine’s lifespan well beyond the warranty period.

How fast is the 4 Wheel Bottle Screw Capping Machine?

The speed of the 4 Wheel Bottle Screw Capping Machine varies depending on the model and production requirements. The Biling Machine is designed for high-speed operations and can cap hundreds of bottles per hour, depending on factors like bottle size and cap type. The machine can be adjusted to match the speed of your production line, ensuring continuous operation without compromising the quality of the capping process. Its efficiency and speed make it an ideal solution for businesses that require quick and reliable capping on a large scale.